Materials for the wind turbine blade market include resins of glass fiber reinforced polyester glass fiber reinforced epoxy and carbon fiber reinforced epoxy. According to a report from the national renewable energy laboratory wind turbines are predominantly made of steel 71 79 of total turbine mass fiberglass resin or plastic 11 16 iron or cast iron 5 17 copper 1 and aluminum 0 2.

Why Wind Turbine Blades Are Made Of Composite Materials Wind Farms Construction

Although the most dominant material used for the blades in commercial wind turbines is fiberglass with a hollow core other materials in use include lightweight woods and aluminum.

Wind turbine blades materials. Wind turbine blade materials. Wooden blades are solid but most blades consist of a skin surrounding a core that is either hollow or filled with a lightweight substance such as plastic foam or honeycomb or balsa wood. Are manufactured from metals.

Blades are the most important composite based part of a wind turbine and the highest cost component of turbines. Wind speeds up to 90 km h blade tip speeds up to 300 km h strong uv radiation and weather. Combining glass fibers with a resin matrix results in composites that are strong lightweight corrosion resistant and dimensionally stable.

Optimization of the shape and material of the blades should allow for the blade to spin faster and capture wind at lower velocities to increase turbine efficiency. The selection of material for wind turbine blade is an important stage in blade design. Turbine engineers know that blades made from carbon fiber weigh 25 less than ones made from traditional fiberglass and that carbon fiber blades could be longer than fiberglass ones and capture.

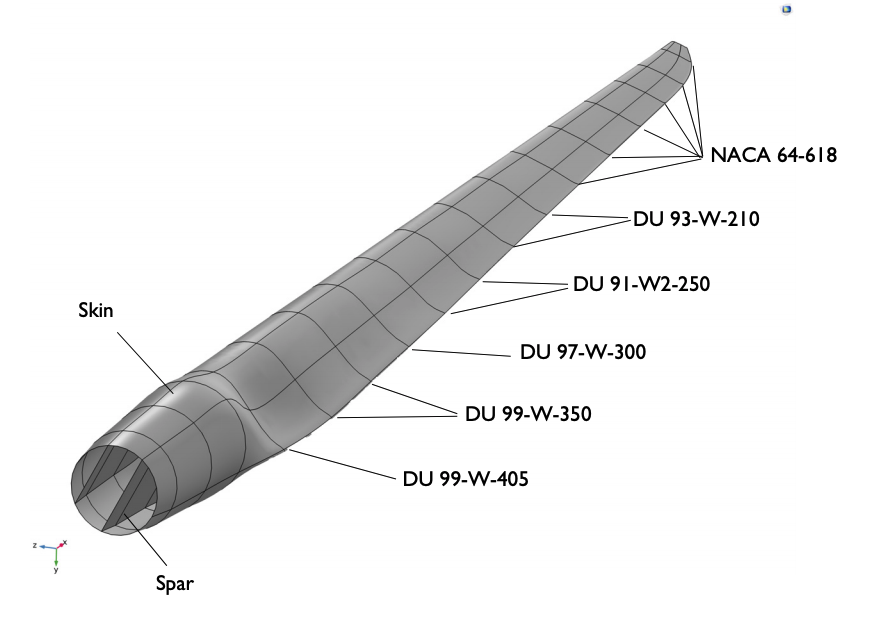

Apart from the traditional composites for wind turbine blades glass fibers epoxy matrix composites natural composites hybrid and nanoengineered composites are discussed. In development constructors must make many decisions from the blade type to the structure and design. The shape of the rotor blade must be aerodynamic much like the wings of an airplane.

This paper presents a simple analytic hierarchy process for material selection for the small wind turbine blade. That material could make wind turbine blades lighter lower cost and more recyclable according to the research. Overview of blade design composite materials are used typically in blades and nacelles of wind turbines.

Wind turbine blades are permanently exposed to high stress. We support you in production with high performing materials. Thermoplastic resins are materials which can be converted into liquids in high heat.