To understand this process with a simple illustration you can take a piece of paper and add waves in it known as flutes. Steam is vital to the corrugated box making process.

The Production Of Modern Corrugated Packaging Fefco

The Production Of Modern Corrugated Packaging Fefco

Corrugated cardboard manufacture includes two key steps.

Corrugated cardboard manufacturing process. Electricity water 1 paper mill customers conversion process. A process of manufacturing of corrugated cardboard type packaging container in which a corrugated core liner adhered at its one side surface to one side liner is applied at its other side surface with an adhesive agent and then with a reinforcing agent and thereafter is adhered to the other side liner to form reinforced corrugated cardboard and before completion of hardening of the. The auxiliary facilities that are used at a corrugated packaging plant.

The corrugated paper manufacturing process. Cardboard as you are likely to be aware of is manufactured using fibres from trees plants. From making the adhesive that conditions the layers of paper to heating the pressure vessels that bond the fluted medium to the liners steam generation is an invaluable process.

Corrugated cardboard boxes manufacturing unit with printing manufacturing plant detailed project report profile business plan industry trends. The process for making corrugated boxes involves six steps that begin with sustainable timber harvesting and finish up in a specialty carton plant like the one used by fg s. Pulp is not only produced from timber but can also be created in an environmentally friendly way by recycling woodchips and shavings leftover from lumber mill waste.

Kraft paper involves pulping wood chips and then feeding the resulting paper substance through massive steam rollers that remove the water. Manufacturing process 16 1 corrugated board manufacturing process 16 2 corrugated board box manufacturing process 17. Before being recycled this waste used to be disposed of at landfills or was burnt.

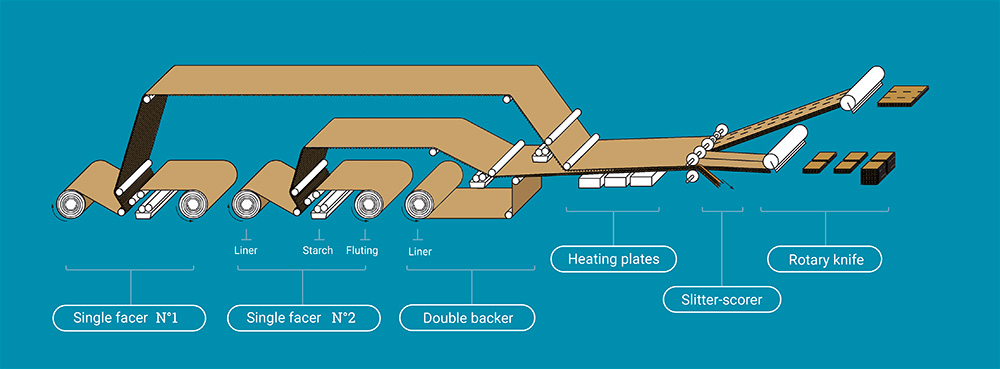

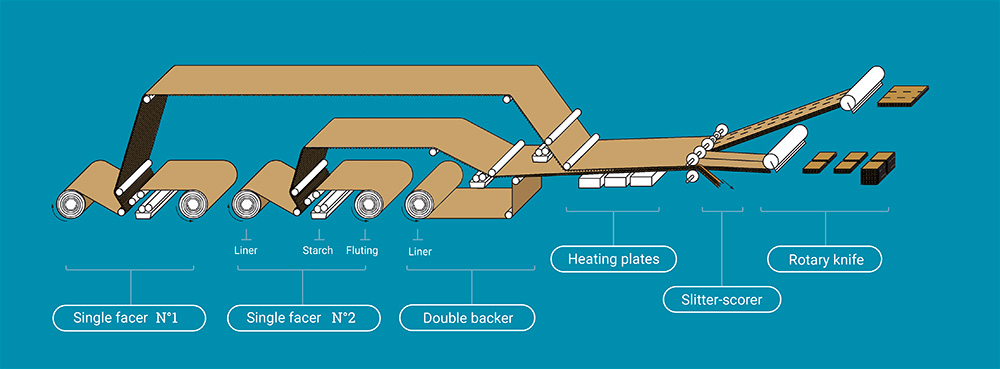

Making kraft paper and corrugating the cardboard. Figure 1 overview of manufacturing process flow for corrugated packaging the discharge of all class i designated chemical substances at the points indicated by the dotted boxes graphic are subject to reporting. Corrugating is also done in a machine that utilizes heavy rollers.

The corrugated board production process is to first print the facial tissue and then combine it with corrugated medium paper and cardboard. The invention relates to a process for manufacturing corrugated board in which the corrugated board is produced by gluing at least three individual constituent webs 3 5 7 respectively on two sides oriented toward each other wherein in a single work cycle at a first glue application point a a first constituent web 3 is coated with glue and at a second assembly point b the first constituent web 3 is glued to a second constituent web 5 to form a half finished web 31 and. The printing process is an flexo with water base liquid with nylo rubber stereo.

Even though the condensed steam is reprocessed the cost of boiler fuel is a large factor in packaging manufacturing. The 1st one is while making 3 ply 5 ply board sheet the top paper is printed separately pasted. Semi automatic corrugated board production line production process.

The corrugated cardboard produced by the process is conventionally formed into a box by using die cutting indentation and sticking. There are various methods of this process. The 2nd process is directly to print on 3 ply 5 ply board sheet.