Kraft applied for the first u s. The first step to making cheese is acidification.

Cheese Making Basic Concepts Concentrol

Cheese Making Basic Concepts Concentrol

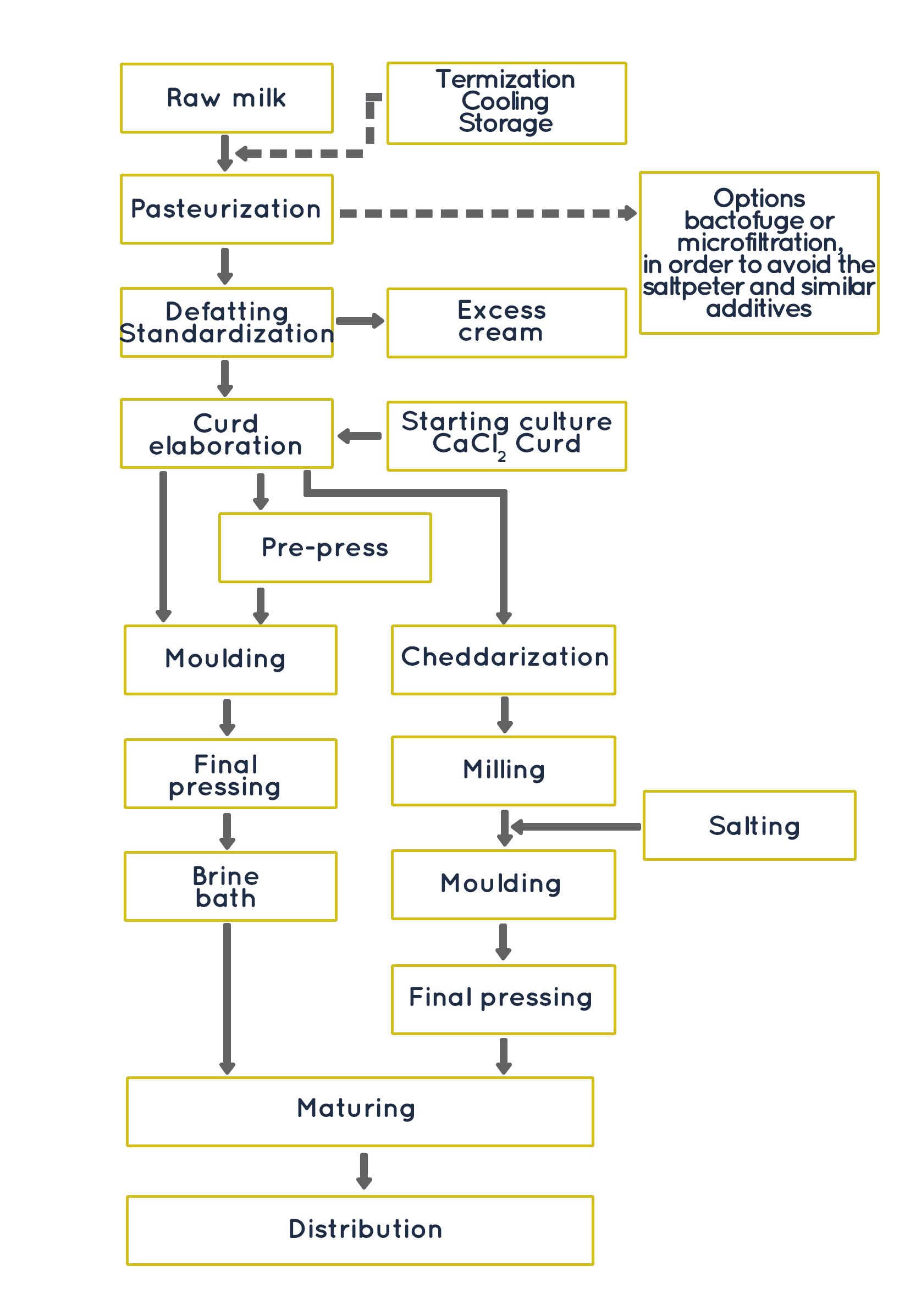

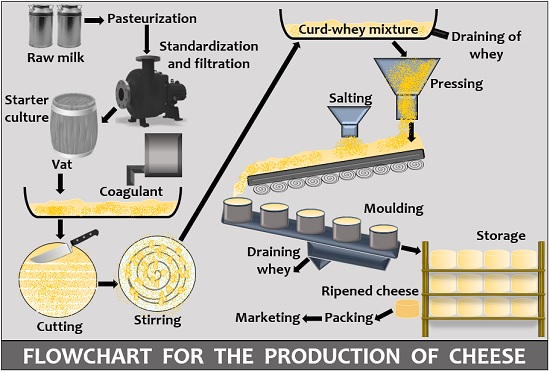

The process of cheese making involves sequential steps like acidification coagulation separation of curd and whey salting moulding ageing and packaging.

The process of cheese. Cheese is made using cow goat sheep water buffalo or a blend of these milks. Then the curds fatty lumps are separated from the whey protein liquid after which the curds are salted and shaped into a wheel or block to age. One way is to dump acid vinegar or citric acid right into the milk to get the correct acidity.

Processed cheese is a food product which begins with real cheese such as cheddar or colby and is created by adding ingredients such as food coloring salt and emulsifiers. Cheese making has long been considered a delicate process. This changes the.

To make cheese the cheesemaker brings milk possibly pasteurised in the cheese vat to a temperature required to promote the growth of the bacteria that feed on lactose and thus ferment the lactose into lactic acid. Kraft received the first patent for his version of the product. While the recipes for all cheeses vary these steps outline the basic process of turning milk into cheese and are also used to make cheese at home.

This process called direct acidification leads to cheeses such as ricotta and mascarpone. Processed cheese typically contains around 50 60 natural cheese. It tandelizes the taste buds by providing a variety of high quality vegetarian nutritive cheese like cheddar mozzarella gauda in various forms like cheese blogs cubes slices cheese tin cheese spread and many more in many flavors.

Additional ingredients such as vegetable oils salt food coloring or sugar may be included. Depending upon the processing method cheese can classify into two types namely rennet and processed cheese. Real cheese is made by heating milk and adding in natural enzymes and bacterial cultures.

Its origins are in the u s when in 1916 canadian american businessman james l. World s most loved product cheese has a fascinating processing journey. Processed cheese is a food product made from cheese and other unfermented dairy ingredients mixed with emulsifiers.

As a result many flavors colors and textures of processed cheese exist. India has the largest production of vegetarian cheese. Patent covering a new method of p.

The main ingredient in cheese is milk. Numerous varieties of cheese exist because ending the simple preparation process at different points can produce different cheeses as can varying additives or procedures. During this stage a starter culture is added to milk that will change lactose milk sugar into lactic acid.

Processed cheese was created in 1911 by swiss inventor walter gerber but in 1916 american james l. Process although cheese making is a linear process it involves many factors. Natural cheese is often aged for an extended period of time anywhere from a few days to many years.

Process cheese is made using natural cheese plus other ingredients that are cooked together to change the textural and or melting properties and increase shelf life. There are many ways to make cheese but the first split in the road is how you acidify the milk.