The chemical process involved in this type of manufacturing is called saponification. Saponification the chemical reaction between any fat and sodium hydroxide is a saponification reaction.

Instrumentation And Process Control In Soap Making Industry

Instrumentation And Process Control In Soap Making Industry

Saponification process for soap manufacturing involves hydrolysis of esters under basic conditions to form an alcohol and the salt of a carboxylic acid carboxylates.

Manufacturing process of soap. The fatty acids can then react with a carbonate salt in order to produce soap. Soap manufacturing process soaps are the product of the reaction between a fat and sodium hydroxide. After batching is complete the product is tested to make sure ingredients were added in the correct proportions.

This is a traditional method of soap making that is usually to process soap at home. Some of these tests evaluate the product s physical properties such as viscosity and ph. Fat 3naoh glycerine 3 soap soaps are produce industrially in four basic steps.

Here the composition of oil changes with the help of the lye to create a bar of soap. Saponification involves the splitting of a fat into fatty acids and glycerin. Soap needs to be about 30 water to be easily pumpable and even then needs to be held at around 70oc so excess lye is added to hydrate the soap and dissolve out some of the glycerine.

Acid slurry is a sulphonation product made by sulphonation of linear alkyl benzene by oleum or so3 or sulphuric acid or combinations of above. It is made by combining fatty acids with sodium hydroxide lye this fatty acids are usually in the form of beef tallow olive oils and hemp oil. The french chemist eugene michel chevreul put the soap forming process called in english saponification into concrete chemical terms in 1823.

The soap and detergent industry is profoundly lucrative with splendid market potential as well as bright future scope. Saponification process for soap manufacturing. Essentially the soap manufacturing process is the combination of fats and a strong alkaline substance resulting in a chemical process called saponification.

It is used in manufacturing of various detergents. During the manufacturing process the quality of the ingredients is chemically tested before batching begins. Moreover soap could not be produced by small makers because of a law that stipulated that soap boilers must manufacture a minimum quantity of one imperial ton at each boiling.

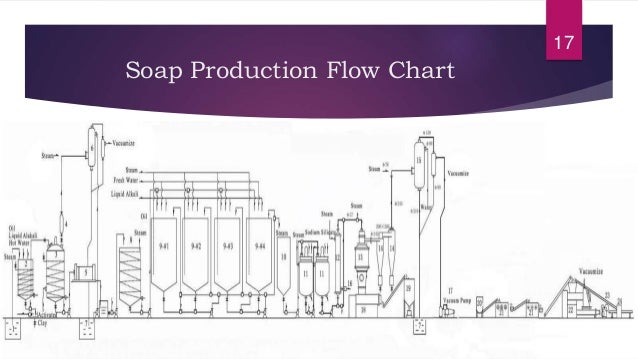

The soap manufacturing process was closely supervised by revenue officials who made sure that soapmakers equipment was kept under lock and key when not being supervised. Figure 1 the colgate palmolive continuous soap manufacturing process xi detergents a soap 5 these ingredients alone would give a low water high glycerine soap. In saponification the animal fat which is chemically neutral splits into fatty acids which react with alkali carbonates to form soap leaving glycerin as a byproduct.

The cold process of making soap involves the mixing of fixed oils preferable olive coconut and palm oils in fixed proportions with an alkali like sodium hydroxide or lye. Saponification processes are chemical soap manufacturing processes that produce soap from fatty acid derivatives.