Lightly sand out any flaws with a low grit sand paper such as 100 grit. These boards will compose the front and back of the bat house.

3 Ways To Make A Baseball Bat Wikihow

3 Ways To Make A Baseball Bat Wikihow

Use a pencil and a speed square to mark 26 from the end on one board then stack all three boards to be cut on the chop saw at the same time.

How to make a wood bat. The process for making a wooden bat can be pretty involved but we would be remiss in not mentioning the most important part of the process which starts working long before we do. The straighter and tighter the grain the less chance it will break when you use it. Fast forwarded video of the start to finish making of a wooden baseball bat.

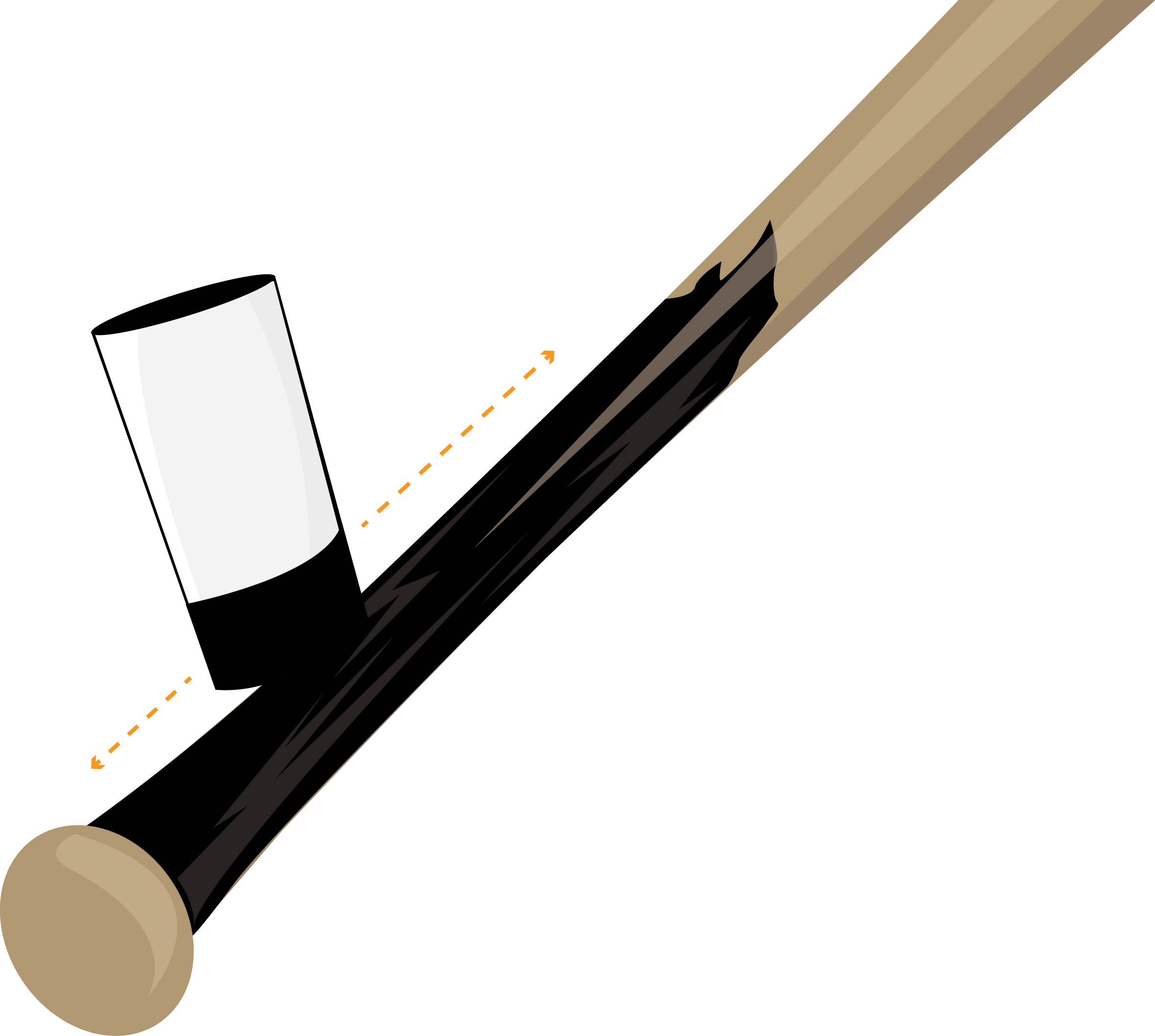

Measure 22 on the remaining length and then use the chop saw to cut all three boards down to size. Lay the gouge against the tool rest and slide the chisel along the handle of the bat. Once both cuts are made align your spur center as straight as you can in the wood and then give it a couple of taps with your rubber mallet to make sure it catches those edges.

Remove wood along the handle until the diameter of the entire handle section reaches 2 inches. After you have achieved this thickness reduce the rotating pace of the lathe to 200 rotations per minute. To get the best bat possible you need the right piece of wood.

Turning sanding caping and painting. Use the roughing gouge to narrow the wood on the handle end of the bat to 2 inches. At the end of the video there.

The first thing to do is to find a good blank of either hard maple or northern ash. The weight is checked and after that it is again placed on the modern lathe machine that gives it a rough baseball bat shape. Once the wood is rotating smoothen the wood to 2 thickness using a roughing gouge.

Material that s been graded for making bats is much better than what you find at the local hardwood store. Slowly slide the chisel up and down the handle to make it narrower. First the wood is placed in the modern lathe that makes it a cylindrical shape.

Finally you are going to want to look for any flaws in the wood do so by hand and sight. One of the modern lathe machines takes approximately 3 minutes to give the raw wood a rough shape of a bat. After the wood is firmly clipped onto the lathe rotate it at a 600 rpm pace.

The rough size should be approximately 3 round and 36 long.