This high temperature compressed air is then cooled in the external refrigeration system. Air inside a distillation column is separated at cryogenic temperatures to produce high purity nitrogen with 1ppm of impurities.

Lab Gas Nitrogen Generators Nitrogen Gas Generation

Lab Gas Nitrogen Generators Nitrogen Gas Generation

The expansion of the process gas cools the cryogenerator s condenser head.

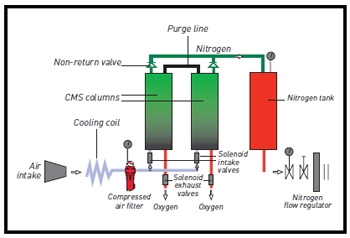

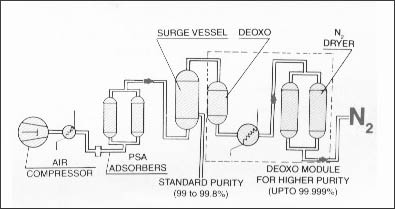

Nitrogen plant working principle. Mainly oxygen is absorbed on the carbon molecular sleve and nitrogen enriched gas is leaving the absorber. In case a higher product pressure is required a downstream nitrogen compressor will be applied. The swing adsorption process in each of the two adsorbers consists of two stages running for a few minutes.

The nitrogen product is normally delivered between 4 barg to 9 barg 60 psig to 130 psig. When the compressed air is passed through one of the adsorbers the molecular sieve absorbs nitrogen. When nitrogen overflows the adsorber the inlet flow is changed to the 2 nd adsorber.

Alkalinity is easiest defined as the ability to resist a drop in ph. Liquid helium plant. The process is based on the air separation which was invented by dr.

Pressure swing adsorption with cryogenerator. With this process nitrogen is produced by the plant at the above atmospheric pressure while the adsorbent regeneration is accomplished at below atmospheric pressure. There are two methods through which nitrogen can be liquefied.

Non condensable gases argon are removed from the condenser head. The nitrogen flows over the condenser head and is thus condensed. Distillation of liquid air.

This is very important because for every 1 part ammonia nh3 converted to nitrate no3 7 1 parts of alkalinity are depleted and for every 1 part nitrate no3 removed 3 6 parts alkalinity. Linde s psa systems have proven to be success ful in cases where performance flexibility availability and reliability are the determining factors. Carl von linde in 1895.

Subsequently the liquid nitrogen is stored in a storage tank. The process is repeated between high pressure and low pressure. Working of psa nitrogen plant working principle uses two vessels which are filled with zeolite molecular sieve as adsorbers.

Refractory nitrogen is the nitrogen that can t be biologically decomposed. Adsorption is a gas separation process whereby the gas molecules adhere to a surface when under pressure. Nitrogen generation plant based on the psa process consist of two adsorbers filled with carbon molecular sleve cms.

Working principle of liquid nitrogen plant. Nitrogen as an element of great technical importance can be produced in a cryogenic nitrogen plant with a purity of more than 99 9999. The process makes the 1 st adsorber functional by eliminating nitrogen by decreasing pressure.

In a liquid nitrogen plant the atmospheric air is first compressed to 7 bar pressure into compressor. How psa nitrogen plant works. Compressed and purified air is passes through the absorbers.