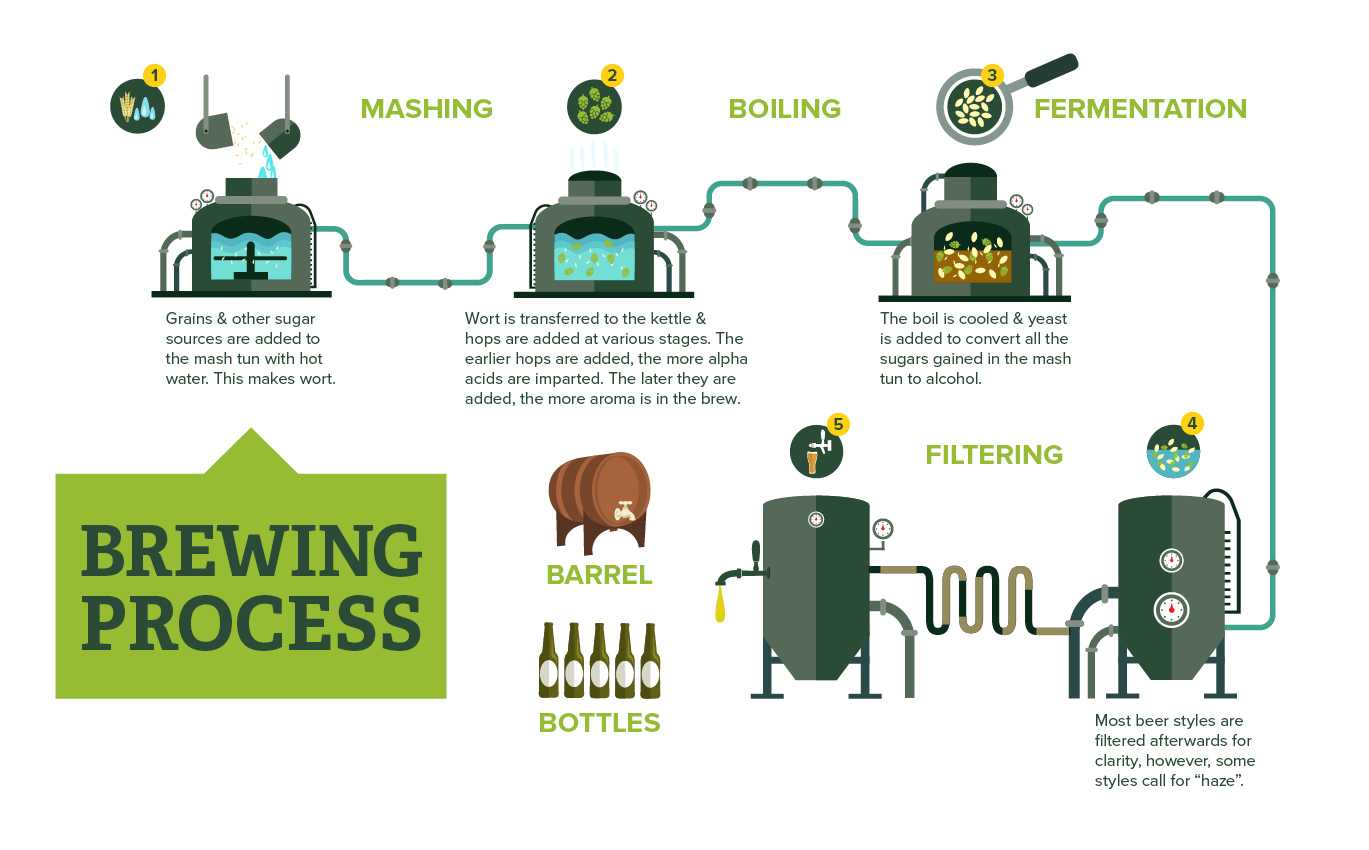

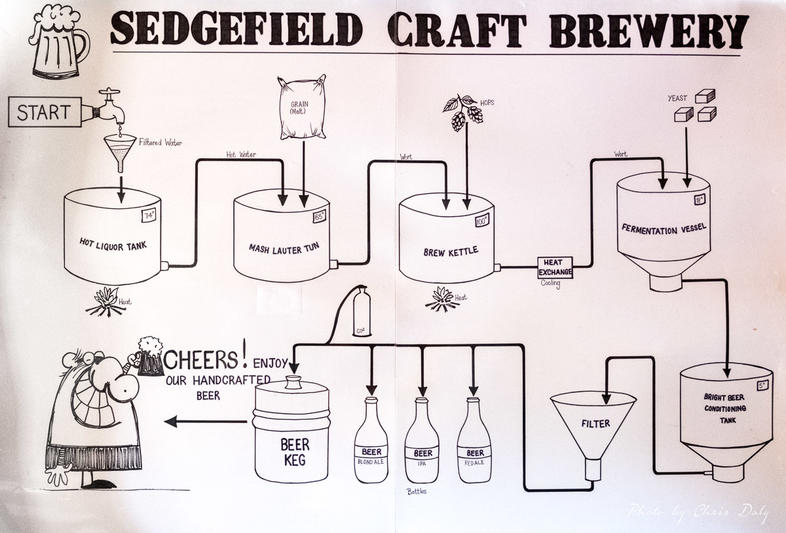

The 4 basic steps. Mash conversion the grist is then transferred into a mash tun where it is mixed with heated water in a process called mash conversion.

Use Of Hops In Brewing Hop Growers Of America

Use Of Hops In Brewing Hop Growers Of America

Brewing was initially a cottage industry with production taking place at home.

How breweries make beer. Beer is brewed from cereal grains most commonly from malted barley though wheat maize corn and rice are also used. Brewing beer at home is easy. Add your crushed grains.

Turn off the heat and cover the brew pot to let the magic take place inside for 30 minutes. Beer yeast is cultivated especially for use in brewing. If you can make mac and cheese from a box without help you can make beer.

You ll also need cracked grains liquid brewing yeast liquid malt extract hops extra spices for flavoring and conditioning tablets. There are two broad categories of beer yeast. In ancient mesopotamia brewers derived social sanction and divine protection from the goddess ninkasi.

The place at which beer is commercially made is either called a brewery or a beerhouse where distinct sets of brewing equipment are called plant. To brew your own beer you ll need a 6 gallon 23 liter carboy an airlock a stopper a 5 gallon 19 liter pot a grain steeping bag a racking cane a funnel glass beer bottles and a bottle capper. The commercial brewing of beer has taken place since at least 2500 bc.

A brewery or brewing company is a business that makes and sells beer. This is a basic overview for brewing an extract beer recipe click here to learn about all grain brewing. By the ninth century monaste.

Now pour up to 2 1 2 gallons of the remaining water into your brew pot leaving at least 3 inches to the top of the pot. Beer brewing boils down to mixing a mash of malted grain often barley with hops and then fermenting it with lager or ale yeasts. During the brewing process fermentation of the starch sugars in the wort produces ethanol and carbonation in the resulting beer.

Turn on the heat to medium high and bring the temperature up to 150 to 155 degrees. Brewing is the production of beer by steeping a starch source commonly cereal grains the most popular of which is barley in water and fermenting the resulting sweet liquid with yeast it may be done in a brewery by a commercial brewer at home by a homebrewer or by a variety of traditional methods such as communally by the indigenous peoples in brazil when making cauim. Beginning in the brew house different types of malt are crushed together to break up the grain kernels in order to extract fermentable sugars to produce a milled product called grist.

The yeast you choose helps determine the brew you end up with.